Viscoelastic Behavior of Composite Deployable Structures

Researchers

Federico Bosi

Kawai Kwok

Sergio Pellegrino

Description

Fiber reinforced polymer composites are promising candidate materials for making energy-storing lightweight deployable structures, which are packaged by fully recoverable deformation and self-deployed by the energy stored in the structure during folding. As the mechanical properties of polymer composites vary significantly with temperature and time, energy is being dissipated during the stowage duration, which makes the subsequent deployment and shape recovery a complex process to analyze.

A first study proposes a viscoelastic model for a single-ply cylindrical shells based on a two-stages microscale computational homogenization. Starting from the experimentally measured relaxation modulus of the epoxy matrix, the elastic constants of the carbon fiber and the optical observation of composite's microstructure geometry, a first finite-element (FE) homegenization of the tow unit cell (fiber and matrix) has been developed to calculate its relaxation modulus tensor, while a further FE homogenization of the lamina unit cell was necessary to obtain the ABD relaxation matrix. This model have been verified against the experimentally meausered compliance of a single lamina in pure tension and pure bending. Moreover, a comparison between the experimental and numerical behavior of the stowage and deployment of a single-ply tape springs shows a very good agreement if the time-dependent stiffness of the shell elements is based on the proposed multiscale model. Finally, a numerical investigation proves that a single-ply tape spring is not able to deploy against gravity after one year of stowage at room temperature, thus viscoelatic reduction of the strain energy stored represents a key process to take into account in the design of thin-shell deployable structures [1].

Finite-element model of the tow unit cell (a) and the lamina unit cell (b). Longitudinal stretching compliance of a plaine-weave lamina at 40°C.

A second research shows how the deployment of a bistable ultra-thin CFRP tape spring is affected by temperature and long-duration stowage. Analytical modelling of the laminate stiffness is determined by means of the CLA theory, starting from the lamina's relaxation modulus, which is described through the Prony series representation. A stability criterion for cylindrical shells is adopted to evaluate the autonomous unfurling of the tape spring. Both analytical predictions and experimental observations show that the deployment time increases with stowage time and temperature since the viscoelastic relaxation decreases the stored strain energy. Furthermore, it has been proved that eccessive temperatures or stowage might cause a significant delay prior the dynamic deployment, or even an unfolding failure of the structure [2].

Snapshots of the deployment of composite tape spring (a). Latent region of no deployment (b) and evolution of deployment time with an increasing stowage of the specimen (c).

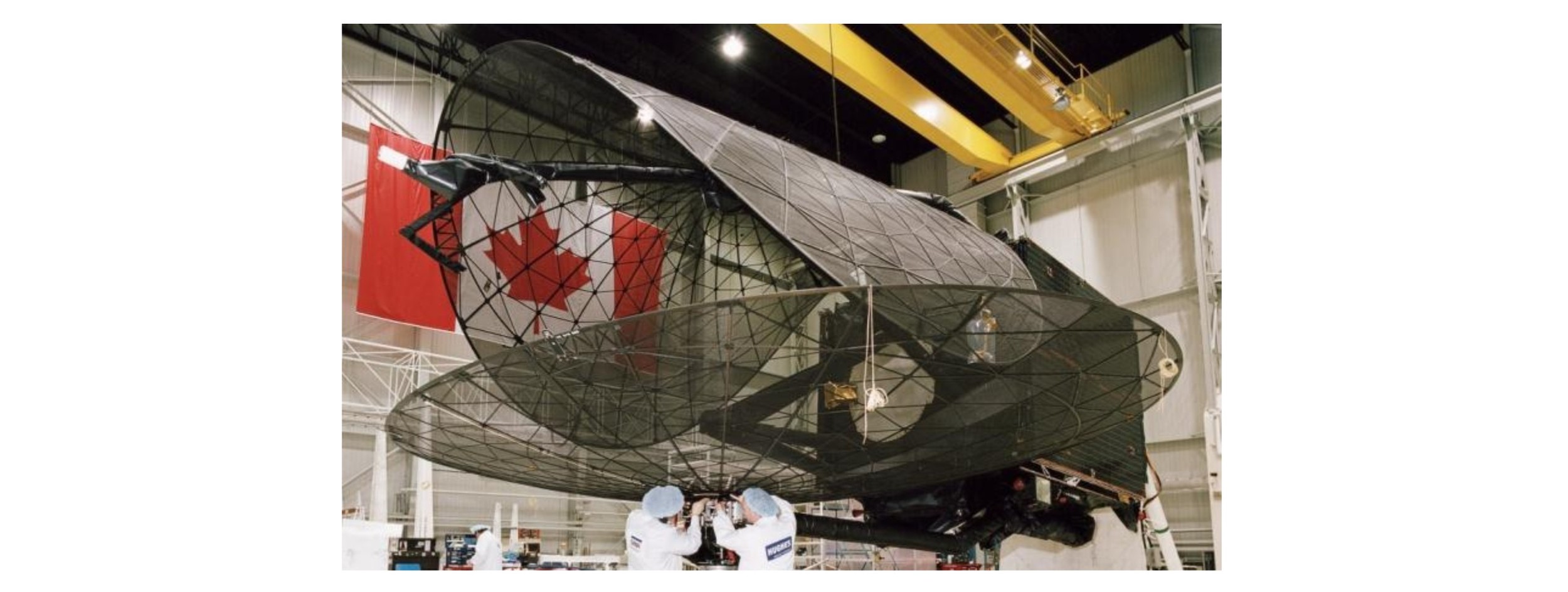

A current invastigation is evaluating the viscoelastic effect of long-term stowage on deployment of composite tape spring hinges and booms.

Publications:

- Kwok, K. and Pellegrino, S. (2016). Micromechanics models for viscoelastic plain-weave composite tape springs. Submitted to AIAA Journal.

- Brinkmeyer, A., Pellegrino, S. and Weaver, P.M. (2016). Effects of long-term stowage on the deployment of bistable tape springs. Journal of Applied Mechanics, 83. (pdf)

- Kwok, K. and Pellegrino, S. (2011). Viscoelastic effects in tape springs. 52nd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, 4-7 April 2011, Denver, CO, AIAA 2011-2022. (pdf)

- Kwok, K., and Pellegrino, S. (2010). Shape recovery of viscoelastic deployable structures. 51st AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, 12-15 April 2010, Orlando, FL, AIAA-2010-2606. (pdf)

Software:

Abaqus/Standard Subroutines described in Kwok and Pellegrino (2016). The UMAT_T300F4uni subroutine computes the relaxation modulus tensor for a viscoelastic tow. The UGENS_T300F4pw subroutine computes the relaxation ABD matrix for a plain-weave composite. [UGENS_T300F4pw] [UMAT_T300F4uni]