Compressive Behavior of Unidirectional Carbon Fiber Reinforced Silicone (CFRS)

Researchers

Ignacio Maqueda

Sergio Pellegrino

Description

Flexible composites are high strain materials made of stiff fibers and a soft matrix. These composites can be deformed into very high curvatures without breaking, due to the relief mechanism provided by elastic microbuckling of the fibers. These materials can be an alternative to thin elements that store strain energy, such as tape springs, to be used in joint-less deployable space structures. Contrarily to tape springs, flexible composites can be folded into curvatures well above the elastic range. These materials can be used as hinges on deployable trusses or as the whole structure for applications like antennas or sunshields.

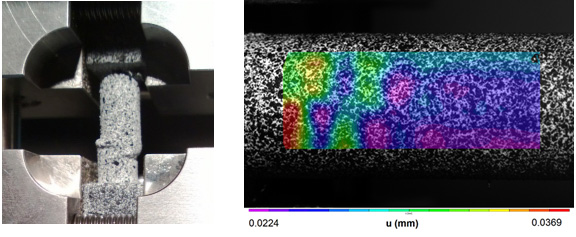

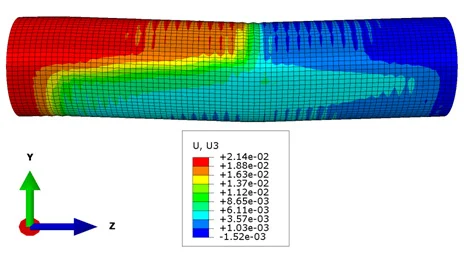

Research on CFRS unidirectional laminas has been conducted to characterize the material properties. Current research is being done on CFRS unidirectional designed and manufactured by L'Garde, Inc. The objective of this research is to develop experimental techniques to characterize the behavior in compression of CFRS, to develop a homogenization model that allows to predict the material stiffness and failure stress and to capture the microbuckling instability with a nonlinear numerical analysis.

Publications:

Maqueda, I., Pellegrino, S., and Mejia-Ariza, J. (2012). Characterization of a high strain composite material. 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, 23-26 April 2012 Honolulu, Hawaii. (pdf)