Lab Facilities

Materials Testing

Instron® electromechanical universal testing machine: Model No.

5569Q9398 with load capacity up to 50kN with maximum loading speed of

500 mm/min and minimum loading speed of 0.005 mm/min.

Number of static load cells with load capacities (compression and tensile):

10N; 500N; 1kN; 50kN

Grips for axial compression and tensile testing

Fixtures for custom loading testing by Wyoming Test Fixtures Inc.:

WTF-EL-194 compression test fixture

CU-FL-96 three and four-point flexure test fixtures

CU-3R-6 three-rail shear test fixture

Two laser Extensometers (non contact) by Electronic Instrument

Research Model No. LE-01 and Model No. LE-05 configured to measure

local axial and transverse displacements with measurement range of

8-80 mm for LE-01 and 8-127 mm for LE-05.

Connections to Instron loading frame through RS232 I/O port.

The Instron environmental chamber fits on the Instron loading frame to

keep the test specimen in controlled thermal environment during

testing. Operating temperature range: +350 deg C and -70 deg. C with

LN2. Temperature Stability: 2 deg. C.

Fabrication of Structural Prototypes

Laser material processing from cutting to engraving of various materials (carbon fiber, metal, plastic ...). This model is equipped with three lasers of different wavelengths and can cut through carbon fiber material. It also has a computer controlled rotating jig option to cut/engrave 3D tubular parts.

Composite Curing Autoclave EC3X6 (3 feet in diameter and 6 feet long curing chamber) by ASC Autoclaves. The ASC composite autoclave utilizes a control system to control the temperature, pressure, vacuum, and cure times based on cure recipes and reading from the sensors that are attached directly to the composite parts and tools during a cure cycle.

The Zund G3-M1600 from Zund, is an automated sheet material processing machine. Equipped with the ability to mechanically cut, crease, or mark, the Zund G3-M1600 is capable of cutting thin sheet materials such as kapton, mylar, composite preforms, and more. For border registrations, the Zund G3-M1600 uses a laser or camera. Additionally, the Zund G3-M1600 has the ability to cut sheet material lengths longer than its working length due to the conveyer belt design that automatically spools given material.

Measurement Systems

Full-field vibration measurement with non-contact laser. Vibrational velocities of 0.01 µm/s to 30 m/s.

Portable coordinate measuring machine with accuracy of 30 μm (contact probe) and 25 μm (non-contact laser probe) over a range of 1.5 m.

Dual camera system composed of two Point Grey monochrome cameras with 5.0 MP resolution and 15 fps maximum frame rate, connected to the VIC-3D Digital Image Correlation software for non-contact measurement of full-field surface displacements and strains.

Stereo camera system consisting of 2 Photron UX100 monochrome high-speed cameras, capable of acquiring up to 80,000 full-resolution (1.3 MP) images at a maximum frame rate of 4,000 fps. Equipped with 35-mm lenses for large field of view imaging. The system also includes a 70,000 lumens REL Sure-Bright LED lighting system with 120 white LEDs. Used to perform Digital Image Correlation (DIC) and photogrammetry on dynamic processes under a wide range of temperatures (0 C to +80 C) and pressures (both in air and vacuum).

The SSL facility is equipped with ZEISS Xradia 510 Versa 3D X-ray microscope (XRM) for high-resolution non-destructive imaging of materials. This allows for full 3D volume scanning of the samples. The objective lenses available allow for X-ray imaging with 0.4 x, 4.0 x, and 20 x magnification. The field of view and the imaging resolution of the scans are highly dependent on sample size and the distance of the X-ray source and X-ray detector from the sample. The spatial resolution of the scans can range from 0.7 – 50 μm. The field of view of the scan ranges from approximately 0.7 – 50 mm. Software available for post-processing include Dragonfly and Avizo for 3D visualization, segmentation, image processing, statistical characterization of defects and voids, and Digital Volume Correlation (DVC).

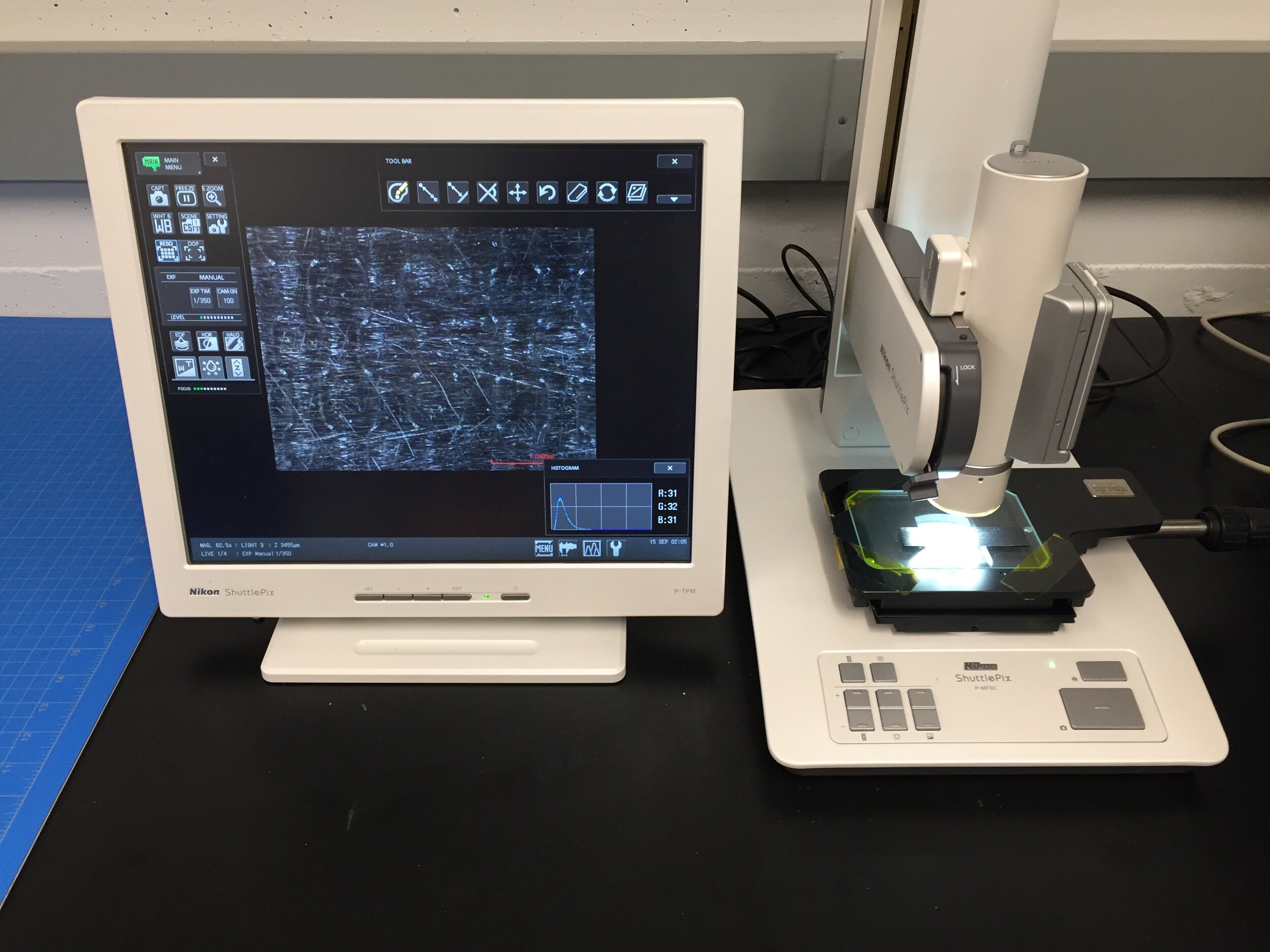

Nikon ShuttlePix P-MFSC is a portable digital microscope. It allows for much simpler remote inspection of large samples that might be too challenging for a conventional microscope. The ShuttlePix can be used for inspection, observation, simple measurements, and recording of high-resolution images.

Optical Structures

-Two laser light sources and a precise flat mirror simulating a star at infinity

-Optomechanics for precise alignment

-A laser light source and a parabolic mirror to simulate a star at infinity

-A Phasics interferometer to measure the wavefront error of the deformable mirror (accuracy : 20 nm rms)

-Electro-optical characterization of CMOS/CCD sensors (measure of bias, dark, flat, noise and gain).

-One thermal vacuum chamber (vacuum up to 10-5 torr,temperature range

-25°C/+60°C) with an optical quality glass window and several ports to test our equipment, electronics and measure temperature

-One optical testbed to measure the wavefront error of mirrors and deformable mirrors being tested in the thermal vacuum chamber